Agitated Thin Film Dryer (ATFD)

Agitated Thin Film Dryer (ATFD)

Agitated thin film evaporators and dryers are used to concentrate, refine or recover a valuable product through distillation or similar thermal separation processes. Due to its inherent design features, it is ideal for thermal treatment of solutions and heat sensitive products, where reduced operating temperatures and vacuum operating pressures are desirable.

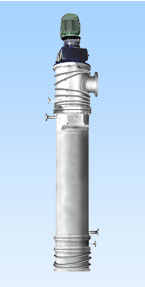

The typical agitated thin film evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The driving speed is adapted to the product being handled, its particular specifications and task.

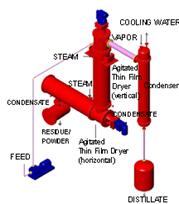

Mechanically Agitated Thin Film Dryer is an indirectly heated continuous dryer. The feed can be in the form of a solution, slurry, wet cake or paste. If required, it operates under vacuum. We offer both vertical and horizontal versions.

How they work :

The vertical Agitated Thin Film Dryer has a jacketed cylinder with a closely fitting rotor at the centre. During operation, the rotor revolves at high speed. The feed distributor spreads the incoming feed uniformly over the cylinder top periphery. The rotor blades pick up the material, spread it over a heated surface in a thin film and agitate the film intensely, as it rapidly travels down. The material transforms from solution to the slurry, wet cake, wet powder and finally dry powder as it travels from top to bottom. The vapour generated rises counter-currently to the inbuilt entrainment separator. Here the entrained droplets are separated from the vapour stream. The clean vapour leaves the dryer through the vapour nozzle at the top.

The horizontal version of the dryer is used for drying of wet cake, pastes, wet powders. The wet feed enters at one end and dry powder leaves from the opposite end. The vapours move counter currently to the powder flow and leave through vapour nozzle.

Features :

• Feeds can be processed without pre-concentration or dilution

• Indirect heating and drying in the absence of air. Particularly effective for heat, light and oxygen sensitive products. Best suited for solvent bearing products for complete solvent recovery

• Quick processing time, best suitable for heat sensitive products

• Probably the most energy efficient dryer in the market. Thermal efficiency exceeds 90%

• Fine powder of uniform consistency can eliminate pulverizer from downstream step

• Intense agitation suppresses fouling, keeps heat transfer surface clean

• Operating pressure under vacuum, up to 1 torr

• Excellent turndown capability

• Low product holdup, ideal for hazardous applications

• Different rotor configurations to suit variety of applications

Applications :

Drying

• APIs, bulk drugs, and intermediates

• Dyes, pigments, and intermediates

• Organic and inorganic salts

Recoveries

• Solvent and products from thick dry residues

• DMSO from salt bearing organic residues

• Glycerine from salt bearing organic residues

• Water from organic and salt bearing waste water streams

Contact Us At

Address

Paramount Limited, Paramount Complex, Near Natubhai Circle, Race Course, Vadodara, Gujarat - 390007

Phone Number

Vadodara: +91-0265-2397111 (7 lines)

New Delhi: +91-11-26186525, 26186369

Mumbai: +91-22-24073108, 24078105

Email Address

Vadodara: sales@paramountlimited.com

New Delhi: delhi@paramountlimited.com

Mumbai: mumbai@paramountlimited.com