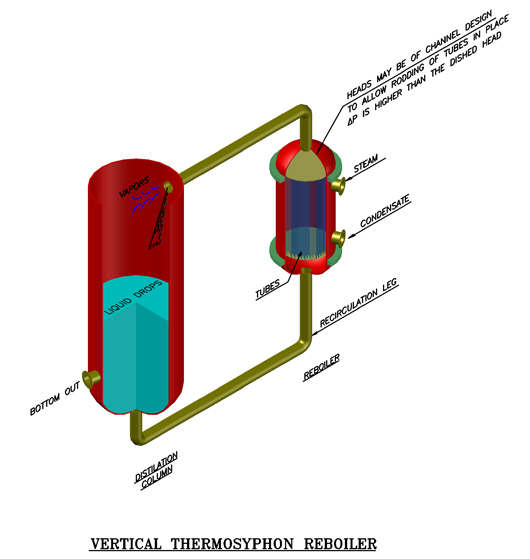

Thermo-Syphon Reboiler

Thermosyphon Reboilers

Thermosyphon reboilers require pumping of the column bottoms liquid into the reboiler. Natural circulation is obtained by using the density difference between the reboiler inlet column bottoms liquid and the reboiler outlet liquid-vapor mixture to provide sufficient liquid head to deliver the tower bottoms into the reboiler. Thermosyphon reboilers are more complex than kettle reboilers and require more attention from the plant operators. There are many types of thermosyphon reboilers including vertical, horizontal, once-through or recirculating.

Thermosyphon reboilers play a wide role in the chemical industry, which provides a simple, low maintenance design for distillation tower reboiler system. The thermosyphon reboiler contains the two endearing qualities of the evaporator, namely mechanical simplicity and operation in the nucleate boiling regime with its attractive high fluxes. These reboilers require rational design procedure as several flow patterns manifests during the heat transfer to a flowing two phase boiling mixture, which in-turn depends on upon the flow rates, physical properties of the components, pipe diameter and orientation. The circulation rate, heat-transfer rate and pressure drop all are interrelated, and hence, iterative design procedures must be used.

Table 1: Advantages and Disadvantages of thermosyphon reboiler

Advantages:

• Cheapest reboiler installation in terms of capital and operating cost

• Permits simple, compact piping arrangement

• Provides excellent thermal performance

Disadvantages:

• Not suitable for viscous or solid bearing fluids

• More heat transfer area required for vacuum operation

• Not specified for pressure below 0.3 bar

• Column base must be elevated to provide the hydrostatic head required for the thermosyphon effect.

• This increases the cost of the column supporting structure.

Features of Construction

In thermosyphon reboilers, performance is determined by the interrelated thermal and hydraulic characteristics, of the reboiler and the interconnecting piping. Circulation is established through the reboiler by the difference between the hydraulic head of the liquid in the column and of the two phase mixture in the reboiler. Raising the liquid level in the column, relative to the reboiler increases this difference in hydrostatic head and thus increases the rate at which the fluid to be vaporized flows through the reboiler.

Contact Us At

Address

Paramount Limited, Paramount Complex, Near Natubhai Circle, Race Course, Vadodara, Gujarat - 390007

Phone Number

Vadodara: +91-0265-2397111 (7 lines)

New Delhi: +91-11-26186525, 26186369

Mumbai: +91-22-24073108, 24078105

Email Address

Vadodara: sales@paramountlimited.com

New Delhi: delhi@paramountlimited.com

Mumbai: mumbai@paramountlimited.com