Surface Condensor

Surface Condensor

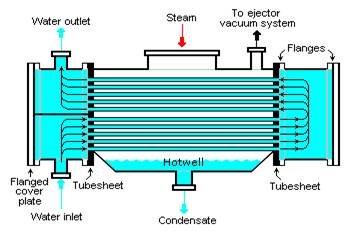

The main Application of heat transfer mechanisms in a surface condenser is the condensing of saturated steam or Vapour on the outside of the tubes of the condenser which is done by circulating Chilled water or Cooling water inside the tubes of the condenser.

Due to the fact that a surface condenser operates under vacuum, non-condensable gases will migrate towards the condenser. The non-condensable gases consist of mostly air that has leaked into the cycle from components that are operating below atmospheric pressure.

These gases can also result from caused by the decomposition of water into oxygen and hydrogen by thermal or chemical reactions.

These gases must be vented from the condenser for the following reasons:

The gases will increase the operating pressure of the condenser. Since the total pressure of the condenser will be the sum of partial pressures of the steam and the gases as more gas is leaked into the system, the condenser pressure will rise. This rise in pressure will decrease the turbine output and efficiency.

- The gases will blanket the outer surface of the tubes. This will severely decrease the heat transfer of the steam to the circulating water. Again, the pressure in the condenser will increase.

- The corrosiveness of the condensate in the condenser increases as the oxygen content increases. Oxygen causes corrosion, mostly in the steam generator. Thus, these gases must be removed in order to extend the life of cycle components.

Surface Condensers prima facie are the generalized terms of a Water Cooled Shell and Tube Type Heat Exchangers that will utilize the heat of a motive liquid or gas to cool the receptive water, or in other words cool the flowing liquid.

Disposal of contaminated water is of growing concern in process operations. Where an ejector system is drawing in contaminants, a condenser that discharges directly to the drain may not be used. For such applications, ejectors using surface condensers are used. The surface condenser prevents discharge to the drain and permits recovery or treatment of undesirable wastes.

A steam jet ejector system with surface condensers normally requires more motive steam and condensing water than the one with direct contact condensers, and is the most expensive.

Key Advantages :

• Decades of design and manufacturing experience

• Compliance with HEI, ASME, PED and other design codes and engineering standards as per project requirements

• Wide range of sizes

• Experience to handle exotic and optional materials and configurations

• Provides individual equipment and consolidated packages

• Erection and Commissioning assistance and service

Contact Us At

Address

Paramount Limited, Paramount Complex, Near Natubhai Circle, Race Course, Vadodara, Gujarat - 390007

Phone Number

Vadodara: +91-0265-2397111 (7 lines)

New Delhi: +91-11-26186525, 26186369

Mumbai: +91-22-24073108, 24078105

Email Address

Vadodara: sales@paramountlimited.com

New Delhi: delhi@paramountlimited.com

Mumbai: mumbai@paramountlimited.com